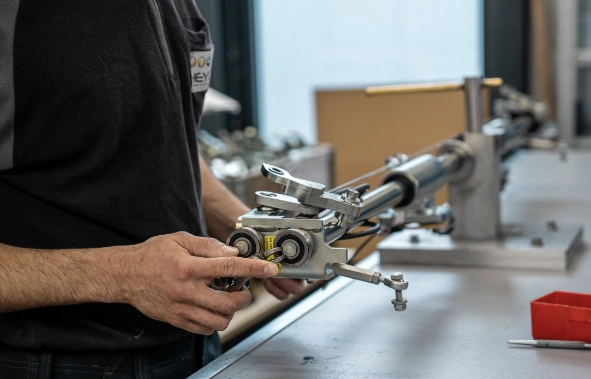

Series assembly: speed and repeatability in perfect balance

A selection of our trusted customers

All-purpose

We provide varying assemblies,from simple to complex.

Efficient

Efficient assembly process thanks toexperience and dedicated staff.

Custom

Tailored process toyour product needs.

Total Partner

We also offer logistics andinventory solutions.

Series assembly is the link between industrial efficiency and consistent product quality. The higher the volume, the more important standardization, preparation and control become. Because where individual assembly still offers room for manual work and flexibility, serial work requires structure, tooling and data. Those who set that up properly benefit from economies of scale, low failure costs and short lead times. Without compromising on quality.

On this page, you will discover what goes into serial assembly.

What makes serial assembly successful?

Efficient assembly begins before the first bolt is tightened. In serial assembly, repeatable processes are crucial. Consider:

- Product-specific clamping jigs

- Clear digital work instructions and checklists

- Pre-setting equipment so machines and tools do not idle

Lean production with short changeover times

In addition to standardization and smart preparation, the SMED (Single Minute Exchange of Dies) principle also plays a role in successful serial assembly. Preparation off the production line – think tooling, measurement data and programs – keeps the production flow continuous.

Consistent quality through process control

With CMM measuring machines, sampling or 100% inspections, quality is made measurable. Critical dimensions are defined, measured and recorded in advance – exactly as they should be in series production.

Chain direction and scalability

Serial assembly requires not only good workplace design, but also smart direction of the supply chain. By strategically sourcing and smartly distributing production, assembly companies can scale up quickly – without sacrificing control or delivery reliability.

Our experts are eager to collaborate with you in providing a comprehensive solution

Get in touch